Comprehensive Insights into Industrial Color Printers: Revolutionizing Electronics Manufacturing with Durafast Label

In today’s fast-paced digital and electronics-driven economy, the importance of high-quality printing solutions cannot be overstated. As businesses strive to differentiate their products through innovative branding, precise labeling, and detailed product information, the role of industrial color printers becomes ever more critical. These robust printing devices are transforming the way electronics companies approach their manufacturing and marketing strategies, enabling unparalleled customization, accuracy, and efficiency.

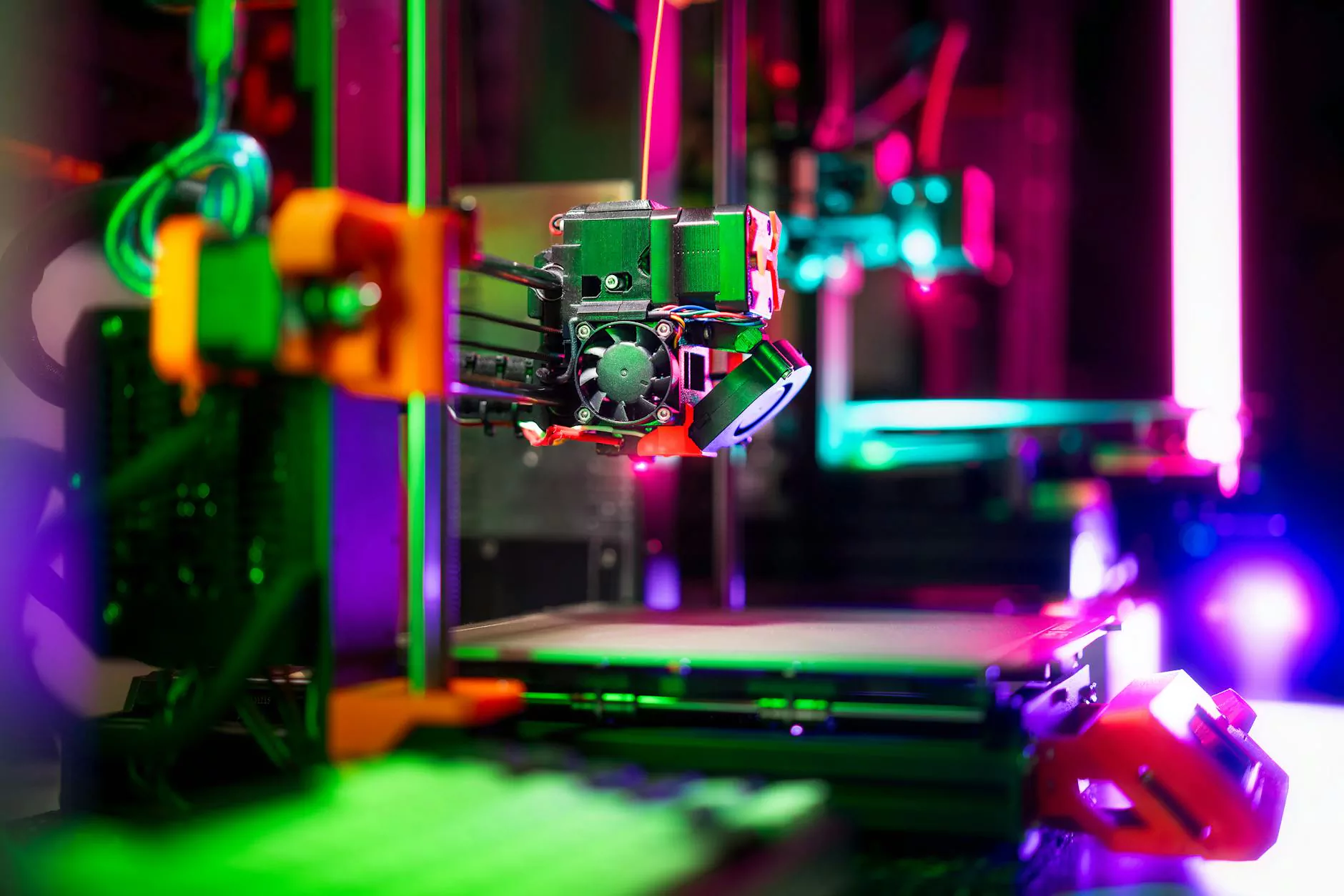

Understanding the Role of Industrial Color Printer Technology in Electronics

The term industrial color printer refers to advanced printing equipment designed for heavy-duty, high-volume production environments. Unlike conventional printers, these machines are engineered to deliver vibrant, consistent, and durable color outputs on a variety of substrates, including plastics, metals, and other materials commonly used in electronics manufacturing.

In the electronics industry, precise labeling and branding are essential—not just for aesthetic appeal but also for compliance, traceability, and safety. Industrial color printers facilitate the creation of detailed circuit labels, QR codes, barcodes, and branding decals that withstand rigorous conditions such as exposure to heat, chemicals, and handling.

The Crucial Advantages of Using Industrial Color Printer in Electronics Manufacturing

- High-Resolution Output: Achieve sharp, vibrant images with crisp text, crucial for detailed circuit diagrams and QR codes.

- Durability and Resistance: Prints produced are resistant to abrasion, chemicals, and environmental stress, ensuring long-lasting labels in harsh conditions.

- Fast Production Speeds: Mass produce labels and branding elements rapidly, increasing throughput and reducing lead times.

- Color Precision and Consistency: Maintain color fidelity across batches, ensuring brand standards and compliance are met accurately.

- Versatility: Ability to print on various materials, including flexible and rigid substrates, vital for diverse electronic components and packaging.

- Cost-Effectiveness: Reduced waste and rework due to precise printing capabilities enhance overall production profitability.

Innovative Printing Technologies Powering the Industrial Color Printer

Cutting-edge printing technologies have paved the way for the superior performance of industrial color printers in the electronics sector. Some of the most notable technologies include:

1. Inkjet Printing for Electronics

This versatile technology allows for high-resolution, detailed prints suitable for intricate electronic components. Inkjet printers designed for industrial use can handle complex circuitry, barcodes, and branding labels with exceptional precision, employing specialized inks that adhere well to electronic substrates.

2. UV Printing

UV curing inkjet printers utilize ultraviolet light to instantly dry inks, resulting in super-durable and vibrant prints on challenging materials such as plastics and metals. This ensures labels and markings for electronics are both visually appealing and highly resistant to environmental factors.

3. Thermal and Laser Printing

These technologies provide rapid, high-precision printing suitable for batch production of barcode labels, serial numbers, and other essential identifiers. They excel in producing consistent, smudge-proof, and high-contrast labels that meet industry standards.

The Significance of Custom Printing Solutions for Electronics Companies

Every electronics manufacturer faces unique challenges—from small batch prototyping to large-scale mass production. Customizable industrial color printing solutions empower these businesses to:

- Enhance Brand Identity: Consistent, vibrant branding on devices and packaging builds customer recognition and trust.

- Improve Product Traceability: High-quality barcodes and serial numbers facilitate tracking throughout the supply chain, supporting compliance and quality control.

- Ensure Safety and Compliance: Clearly labeled electronic components and devices help meet regulatory requirements and inform users about safety standards.

- Streamline Production Processes: Automated and high-speed printing reduces bottlenecks and human errors, increasing overall efficiency.

Choosing the Right Industrial Color Printer for Your Electronics Business

Selecting the optimal industrial color printer depends on various factors specific to your manufacturing needs:

- Print Volume: High-volume operations may require industrial-grade inkjet or laser printers with large media capacities.

- Material Compatibility: Ensure the printer can handle the substrates used in your electronic components and packaging.

- Color Range and Resolution: For detailed branding and small text, prioritize printers offering high resolution and color accuracy.

- Durability Requirements: Consider printers that support inks resistant to chemicals, heat, and abrasion.

- Automation and Integration: Seamless integration with your existing manufacturing workflow and automation systems enhances productivity.

Durafast Label: Your Partner in Premium Printing Services for Electronics

At Durafast Label, we specialize in providing top-tier printing services tailored specifically for the electronics sector. Our state-of-the-art industrial color printers enable our clients to achieve:

- High-Quality Labels: We produce barcodes, serial labels, and branding decals with unmatched clarity and durability.

- Customized Solutions: Our team works closely with clients to develop printing solutions that meet exact specifications.

- Fast Turnaround Times: We prioritize efficiency without compromising quality, ensuring your production timelines are met.

- Competitive Pricing: Cost-effective solutions that deliver outstanding value and return on investment.

- Environmental Responsibility: We utilize eco-friendly inks and sustainable practices to support environmental stewardship.

The Future of Industrial Color Printer Technology in Electronics Manufacturing

As the electronics industry continues to evolve, so too will industrial color printers. Emerging trends include:

- Nanoprinting: Ultra-fine resolution printing for microelectronics and next-generation devices.

- Smart Inks: Development of conductive and functional inks for printed electronics and wearable devices.

- Automation and AI Integration: Advanced systems capable of real-time quality control and adaptive printing adjustments.

- Wireless Connectivity: IoT-enabled printers for remote monitoring and management of printing processes.

Conclusion: Elevate Your Electronics Manufacturing with the Best Industrial Color Printer Solutions

The integration of industrial color printers into electronics manufacturing processes offers significant advantages—from enhanced branding and product traceability to improved durability and efficiency. Choosing the right printing technology and partner, such as Durafast Label, can propel your business forward, ensuring your products stand out in a competitive marketplace. Embrace innovation, invest in high-quality printing solutions, and experience the transformative impact of advanced industrial color printing on your electronics operations.

Whether you are developing prototypes, scaling production, or maintaining strict compliance standards, the right industrial color printer can be a game-changer. Let Durafast Label be your trusted partner in navigating this technological landscape, providing tailored solutions that meet your specific needs and goals.

Get Started Today

Reach out to our team of experts to discover how our comprehensive printing services can revolutionize your electronics manufacturing process. With Durafast Label’s cutting-edge equipment and dedicated customer support, you'll achieve superior quality, remarkable speed, and cost-efficient results—driving your business to new heights.