CNC Precision Machining Manufacturers: Elevating Manufacturing Quality

In the evolving landscape of manufacturing, CNC precision machining manufacturers are at the forefront, driving innovation and efficiency. These manufacturers utilize advanced technology to produce components with exceptional precision and accuracy, significantly impacting various industries.

Understanding CNC Precision Machining

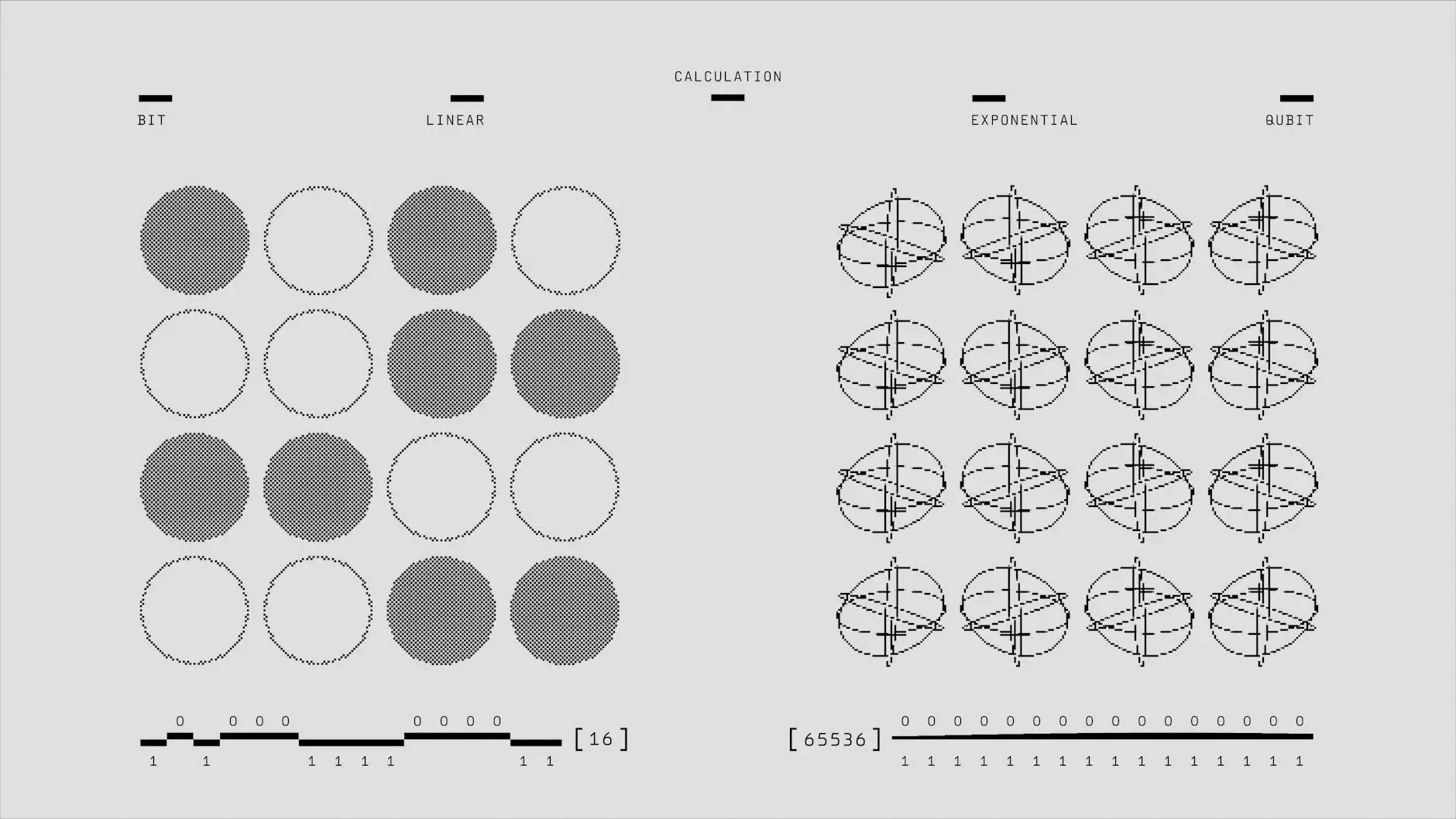

CNC stands for Computer Numerical Control, a technology that automates machine tools through the use of computers executing pre-programmed sequences. Unlike manual machining, CNC machining offers improved accuracy and is capable of producing complex shapes that would be nearly impossible to achieve manually.

Key Components of CNC Machining

- CNC Machines: These machines include lathes, mills, and routers, each designed to work on specific materials with precision.

- Control Software: This software allows operators to input designs and adjust settings for optimal machining operations.

- Materials: CNC precision machining can work with a variety of materials including metals, plastics, and composites, making it versatile for numerous applications.

The Role of CNC Precision Machining Manufacturers

CNC precision machining manufacturers are crucial in producing high-quality components for industries such as aerospace, automotive, medical, and electronics. These manufacturers serve as the backbone of manufacturing, providing reliable and precise parts that meet rigorous standards.

Here are a few reasons why the role of these manufacturers is indispensable:

1. Unmatched Precision

One of the defining characteristics of CNC precision machining manufacturers is their ability to produce parts with extremely tight tolerances. With the aid of CNC technology, manufacturers can achieve tolerances as tight as ±0.001 mm, ensuring that each component fits perfectly within complex assemblies.

2. Consistent Quality

Consistency is key in manufacturing. CNC machining processes are repeatable, which means that a batch of parts can be produced to identical specifications every time. This level of quality control is critical, particularly in industries where safety is paramount.

3. Speed and Efficiency

With CNC machines, the production times are significantly reduced. Once programmed, the machines can operate continuously, turning out a large volume of parts in less time than traditional methods. This efficiency not only reduces labor costs but also enhances productivity across the board.

4. Flexibility in Design

CNC precision machining allows manufacturers to adapt quickly to new designs or revisions. Changes in design can be implemented swiftly through adjustments in the software, minimizing downtime and keeping production on schedule.

Industries Benefiting from CNC Precision Machining

The versatility of CNC precision machining makes it applicable across various industries. Below are some key sectors that benefit greatly from this technology:

Aerospace Industry

The aerospace sector requires components that meet strict safety and performance standards. CNC machining allows manufacturers to produce lightweight, high-strength parts such as brackets, brackets, and housings with unparalleled accuracy.

Automotive Industry

In the automotive industry, CNC precision machining is used for creating everything from engine components to custom parts for high-performance vehicles. Manufacturers can produce parts that are not only precise but also durable and reliable under extreme conditions.

Medical Devices

The medical field demands the highest standards of precision. CNC machining plays a vital role in producing surgical instruments, implants, and other critical components where accuracy can directly affect patient outcomes.

Electronics

CNC precision machining is also integral to electronics manufacturing, where complex shapes and precise dimensions are vital. Components such as circuit boards and housings must meet tight specifications, ensuring functionality and reliability.

Choosing the Right CNC Precision Machining Manufacturer

Selecting the right CNC precision machining manufacturer is crucial for ensuring the success of your project. Here are several key factors to consider:

1. Experience and Expertise

Look for manufacturers with extensive experience in the industry. A company that has been in business for several years is more likely to overcome challenges and deliver high-quality products.

2. Technology and Equipment

The technology used by CNC machining manufacturers can greatly influence the quality of the work produced. Manufacturers should be equipped with the latest CNC machines and technology to ensure high precision and efficiency.

3. Certification and Compliance

It’s important to choose manufacturers that comply with industry standards and certifications. This compliance helps ensure that products meet specific quality and safety requirements.

4. Customer Support and Communication

Effective communication is vital in any manufacturing process. Choose a manufacturer that offers strong customer support and is willing to work closely with you throughout the project.

The Future of CNC Precision Machining

The future of CNC precision machining looks exceptionally promising. As technology continues to evolve, several trends are emerging that are set to reshape the industry landscape:

1. Automation and AI Integration

With advancements in artificial intelligence, manufacturers are beginning to integrate AI into CNC machining processes, allowing for smarter, self-optimizing operations and predictive maintenance that reduces downtime.

2. Increased Use of Advanced Materials

New materials such as composites and superalloys are being developed, and CNC precision machining systems are being adapted to work with these advanced materials, expanding their application scope.

3. Sustainability Initiatives

As industries become more conscious of their environmental impact, CNC precision manufacturing is also adapting. Efforts are being made to reduce waste through efficient machining processes and the use of sustainable practices.

4. Customization and Rapid Prototyping

As customers demand more customization, CNC manufacturers are stepping up by offering rapid prototyping services. This ability to quickly create prototypes allows for more immediate feedback and faster product development cycles.

Conclusion

The role of CNC precision machining manufacturers in modern manufacturing cannot be overstated. Their ability to deliver unparalleled precision, quality, and efficiency opens up countless possibilities across various industries. As technology advances, these manufacturers are poised to lead the way into an exciting future of innovation and excellence in manufacturing.

For businesses seeking top-notch CNC precision machining services, Deep Mould stands out in the market, offering expertise in metal fabrication and the commitment to quality that modern businesses demand.